If you have spent any time around electrical work in the UAE, you have probably heard this question more times than you can count. Should we use single core or multi core?

On paper, the difference looks technical. In real life, it is practical. It affects how easy the installation is, how neat the final work looks, how heat behaves inside conduits, how maintenance is handled later, and sometimes how long the system actually lasts in UAE conditions.

This is not a textbook explanation. This is about how Single Core Cables and Multi Core Cables behave when they are actually installed in villas, towers, warehouses, sites, and industrial spaces across the UAE.

Why This Question Matters So Much in the UAE

Electrical installations here are not forgiving. Heat, dust, long cable runs, tight conduits, and high load demands all put pressure on wiring choices.

You can technically make both single core wire and multi core cables work in many situations. But one choice almost always works better than the other.

And when the wrong choice is made, the problems usually show up later. During inspections. During expansions. Or worse, during faults.

What Are Single Core Cables?

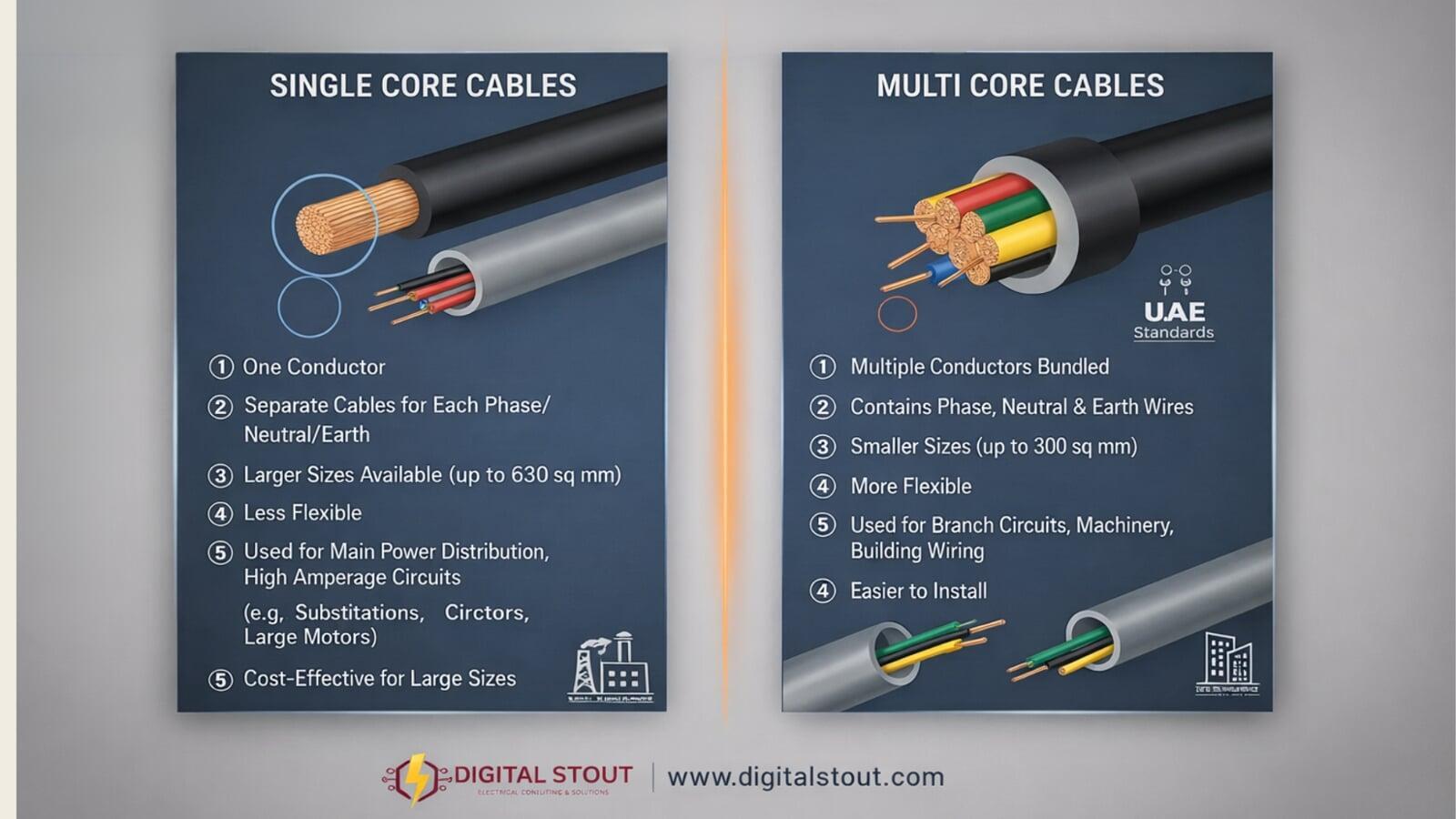

A single core wire is exactly what the name suggests. One conductor. One core. One insulated wire.

That conductor is usually copper or aluminum, covered with insulation suitable for the application. No more, no less.

In practice, single core cables are used in groups. A phase wire. A neutral wire. An earth wire. Each one is separate.

You see single core wire everywhere in:

- Distribution boards

- Panel wiring

- Conduit runs inside buildings

- Industrial control panels

What Are Multi Core Cables in Real Installations?

Multi Core Cables come up with multiple insulated conductors all tucked within a single outer sheath. They simplify routing, but they also lock you into a fixed configuration.

Typical examples of this cable include the following:

- 2 core

- 3 core

- 4 core

- 5 core and beyond

- Motor connections

- Outdoor power feeds

- Equipment wiring

- Control cables

The Core Difference Is Not the Number of Wires

Many people think Single Core vs Multi Core Cables is just about how many wires are inside. That is surface-level thinking.

The real difference shows up in:

- Installation control

- Heat dissipation

- Maintenance flexibility

- Space management

- Fault isolation

Installation Flexibility: Where Single Core Cables Shine

Single core wire gives installers freedom. You can do a lot things like:

- Route wires differently if space is tight

- Adjust grouping inside panels

- Replace one wire without disturbing others

- Add circuits later more easily

If a single phase needs replacement, you replace one wire. You do not touch the others.

Installation Speed: Where Multi Core Cables Win

Multi Core Cables are faster to install. Moreover, you have ess chance of mixing phases. There is less labeling confusion as well.

On sites where time matters, especially for outdoor runs, quipment feeds and fixed loads, these cables are ideal.

Multi core cables reduce labor time significantly. This is one reason contractors often prefer them for large straight runs.

Heat Behavior Inside Conduits

This is where things get serious in UAE conditions. Heat buildup is a real concern. And how cables handle heat depends on spacing and grouping.

Single core wire installed in conduits allows:

- Better spacing

- More controlled grouping

- Easier compliance with derating rules

For high-current applications, many engineers prefer Single Core Cables because they dissipate heat more efficiently when installed correctly.

Maintenance and Fault Finding

Ask any maintenance electrician what they prefer during fault finding. Most will say single core wire. Because when something goes wrong they can do the following:

- You can isolate one conductor

- You can test easily

- You can replace only what failed

Neatness and Organization Inside Panels

Inside panels, neatness is not cosmetic. It is functional. Single Core Cables allow:

- Clean bending

- Clear routing

- Logical grouping

Outdoor Installations: Multi Core Cables Take the Lead

For outdoor runs, the story often flips. Multi Core Cables offer a lot of things that are ideal for outdoor installations. Some of them include:

- Better overall protection

- Fewer entry points

- Reduced exposure to environment

- Faster installation

Mechanical Protection Considerations

Multi Core Cables have an outer sheath that protects all cores together. This is useful in environments where cables might be:

- Touched

- Moved

- Vibrated

- Exposed to abrasion

Space Constraints Matter

In tight conduits, single core wire can be easier to manage because you can arrange them efficiently.

In long straight runs, multi core cables reduce clutter and pulling effort.

Space is often underestimated during planning. But once conduits are installed, choices become limited.

This is why understanding Single Core vs Multi Core Cables early helps avoid compromises later.

Cost Is Not Just Cable Price

Many people compare only cable prices. That is a mistake. Single core wire may be cheaper per meter, but installation labor can be higher. Multi core cables may cost more per meter, but installation is quicker.

The real cost involves in the following things:

- Cable

- Labor

- Maintenance

- Replacement risk

Safety and Compliance in the UAE

UAE electrical codes and standards often allow both types, but they expect proper application.

Inspectors look at:

- Correct cable sizing

- Proper grouping

- Heat management

- Labeling and termination quality

Where When Single Core & Multi Corr Cables Make Sense

Single Core Cables are ideal in the following conditions:

- Wiring inside panels

- Running high-current circuits

- Planning future expansion

- Expecting regular maintenance

- Managing heat carefully

- Running fixed equipment feeds

- Installing outdoors

- Speed matters

- Space is limited

- Loads are predictable

That is why understanding Single Core vs Multi Core Cables properly makes you a better decision-maker, not just a better installer.

Final Thoughts

Single Core Cables and Multi Core Cables are tools. Neither is superior in all cases.

Single core wire offers control, flexibility, and serviceability. Multi core cables offer speed, protection, and simplicity. The best installations in the UAE use both intelligently.